Notice of the Ministry of Commerce on Issuing Several Policies and Measures for Promoting the Steady Growth of Foreign Trade

All provinces, autonomous regions, municipalities directly under the Central Government and Xinjiang Production and Construction Corps market supervision bureaus (departments, committees), industry and information technology departments, relevant national professional standardization technical committees:

the "Construction Plan for High-quality Standard System for Industrial Base Machines" compiled by the State Standards Committee and the Ministry of Industry and Information Technology is hereby issued to you, please earnestly implement it.

National Standards Committee

ministry of Industry and Information Technology

july 1, 2025

construction scheme of high quality standard system for industrial mother machine

in order to implement the decision and deployment of the CPC Central Committee and the State Council on the high-quality development of the industrial mother machine industry, strengthen the top-level design of industrial mother machine standardization, strengthen chain thinking to build a high-quality standard system for industrial mother machines, accelerate the optimization and upgrading of the industrial mother machine industry with standard upgrading, and enhance the resilience and safety level of the industrial chain supply chain, this plan is formulated.

General 1. requirements

adhere to the guidance of Xi Jinping Thought on Socialism with Chinese Characteristics for a New Era, fully implement the spirit of the 20th National Congress of the Communist Party of China and the Second and Third Plenary Sessions of the 20th Central Committee of the Communist Party of China, and thoroughly implement the "National Standardization Development Outline" and "The National Standard System Construction Plan for Promoting High-quality Development" and other deployment requirements, with the construction of a high-quality standard system for industrial machine equipment as a starting point, strengthen the supply and strengthen the supply chain, accelerate the promotion of domestic and international compatibility of standard systems, maximize the release of standardized efficiency, upgrade traction equipment updates with standards, and continuously enhance the resilience and safety level of the supply chain of the industrial mother machine industry chain.

By 2026, the high-quality standard system for industrial mother machines will be basically established to promote the quality improvement and equipment upgrading of industrial mother machines with the construction of high-quality standard system, and lead the high-quality development of the industry with high-level standards. No less than 300 standards have been revised, and no less than 5 relevant international standards have been revised. The conversion rate of international standards has reached 90%, and the standard supply structure has been optimized. Accelerate the development of high-end industrial mother machines, high-end CNC systems, high-performance functional components, advanced manufacturing processes, key core components and other standards, some key standards are moderately ahead of the average level of industrial development, standards lead the high-quality development of the industry more powerful. Accelerate the transformation of innovation achievements into advanced applicable standards, form a normalized convergence mechanism between common key technologies and standard achievements of applied science and technology plan projects, and make the linkage between standards and industrial science and technology innovation more closely and efficiently.

By 2030, a standard system adapted to the high-quality development of the industrial machine tool industry will be fully formed, the technical level and internationalization of the standard will continue to rise, the efficiency of leading the high-quality development of the industry with standards will be fully demonstrated, the manufacturing standards for reduced materials and other materials will reach the world's advanced level as a whole, and the standard level of some additive manufacturing will reach the world's leading level.

2. construction ideas

pay attention to the linkage between the standard system and the high-quality development of the industry. It should be closely combined with the development direction of industrial mother machines such as the high-end jump of material reduction manufacturing, the strengthening of material manufacturing advantages, and the international leading material addition manufacturing. Standards should be used to help solve the short board and bottleneck of the industrial chain, promote the breakthrough and popularization and application of forward-looking and original standards, and use standards to help realize the simultaneous progress of forging long board, mending short board and fixing bottom board in the industrial mother machine industry.

Pay attention to the integration of standards in the upper, middle and lower reaches of the industrial chain. It is necessary to accurately grasp the actual development of the industry, the trend of research and judgment, fully consider the coordination of the upstream, middle and downstream standards of the industrial chain, strengthen the "chain" thinking, and build a scientific standard system to drive the overall quality of the industrial machine industry.

Pay attention to the compatibility of domestic and international standard systems. We should pay attention to the coordination and compatibility of Chinese standards and international standards, accelerate the adoption of advanced and applicable international standards, promote the transformation of Chinese standards into international standards in a timely manner, actively carry out the simultaneous formulation of domestic and international standards in advantageous areas, and accelerate the promotion of international cooperation in the industrial machine industry with the internationalization of standards.

3. standard architecture and content

(I) architecture

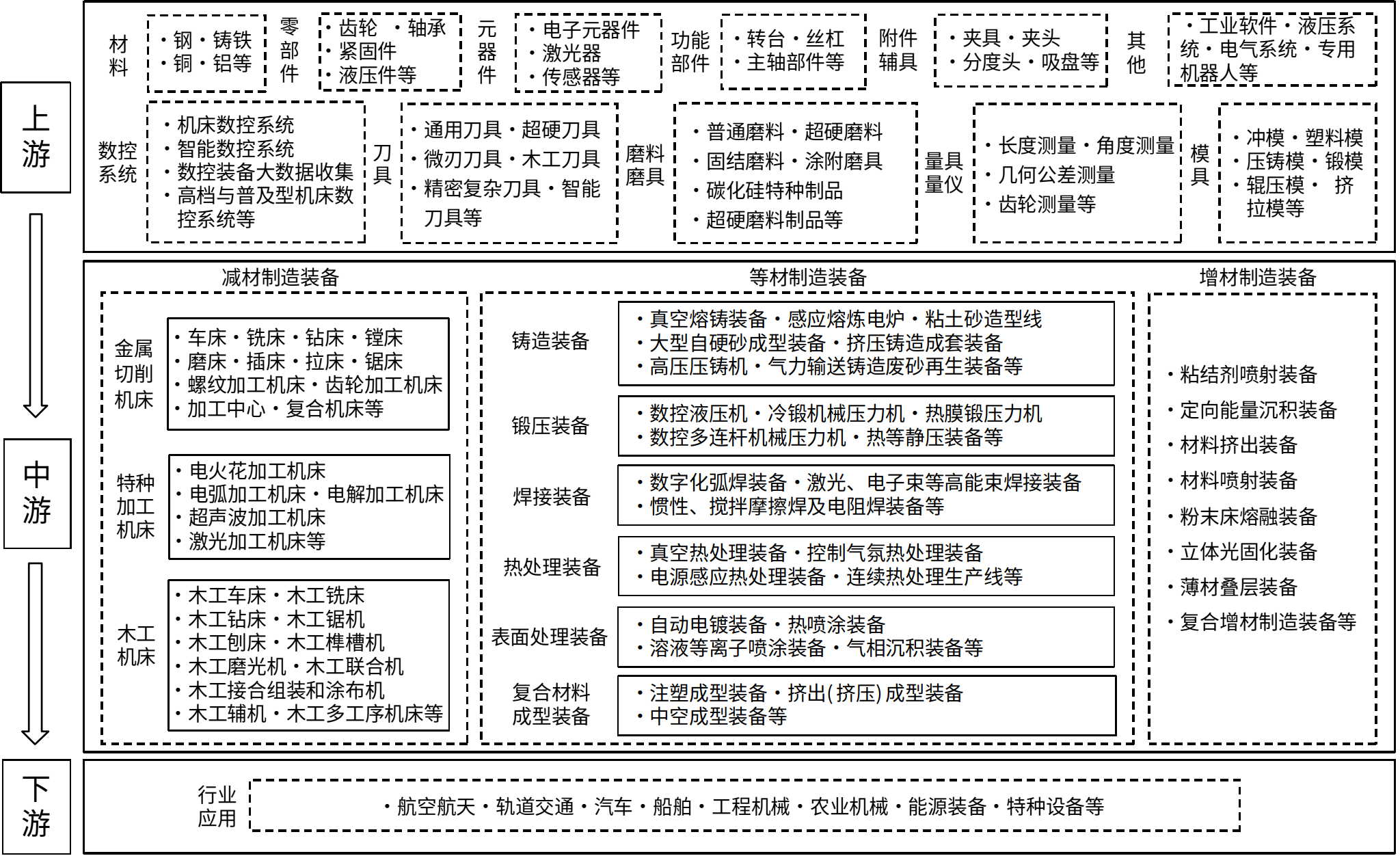

the high quality standard system of industrial mother machine is formed based on the mapping relationship between the industrial chain and the standard. Industrial mother machine industry chain refers to the reduction of material manufacturing equipment, such as material manufacturing equipment, additive manufacturing equipment as the core, from raw materials to end product manufacturing and application of each link of the complete chain, the upstream of the industrial chain covers supporting materials, parts, functional components and other supporting products, the downstream covers aerospace, rail transportation and other applications. The industrial chain of industrial mother machines is shown in Figure 1.

Figure 1 Industrial mother machine industry chain

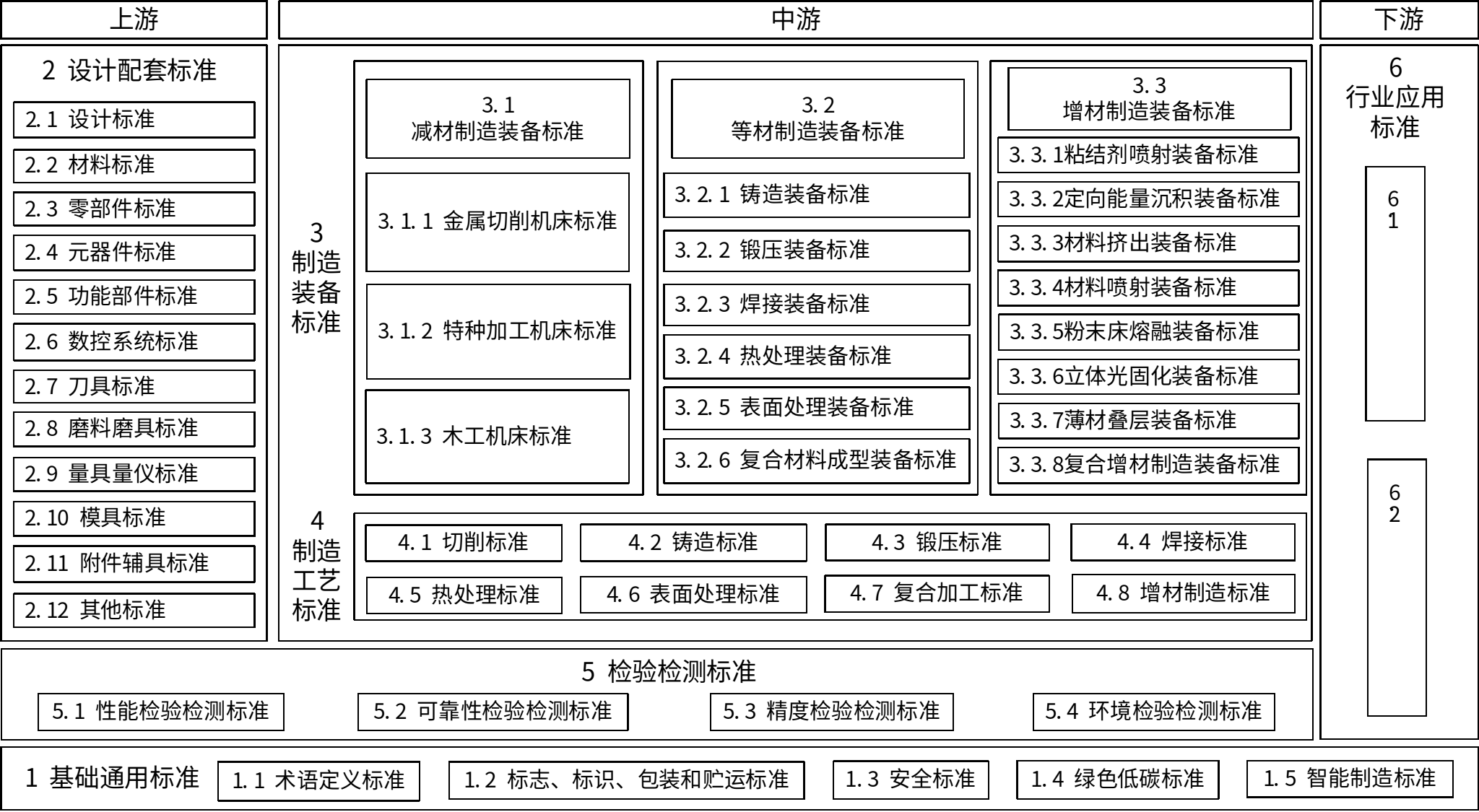

the high-quality standard system of industrial mother machines is a technical standard group that supports the high-quality development of industrial mother machines. Through the mapping of standards with the upper, middle and lower reaches of the industrial chain, the "soft connection" between relevant standards and technologies, products and services is realized ". Among them, the basic general standard runs through the industrial chain of industrial mother machines and is the base of the standard system. The design of supporting standards constitutes the supporting guarantee for the production of industrial mother machines. Manufacturing equipment standards are the core of the standard system and reflect the overall technical level of industrial mother machines. Manufacturing process standards are the key to product molding and affect product quality and cost control. Inspection and testing standards are the basis for evaluating product quality; industry application standards provide technical support for industrial mother machines to empower other industries. The standard architectural relationships are shown in Figure 2.

Figure 2 Industrial mother machine high quality standard architecture relationship

(II) system framework

the high-quality standard system for industrial mother machines is mainly composed of 6 levels, 34 major categories and 17 minor categories, including basic general purpose, design supporting, manufacturing equipment, manufacturing process, inspection and testing, and industrial application, and is dynamically adjusted according to the development of the industrial mother machine industry. The standard system framework is shown in Figure 3.

Figure 3 Framework of high quality standard system for industrial mother machine

(III) system content

1. Basic general standards

-Terminology definition standards: mainly including industrial mother machine special terms, definitions, classification, symbol code and other related standards;

-Marking, marking, packaging and storage and transportation standards: mainly including marking, marking, packaging, storage, transportation and other relevant standards of industrial mother machines;

-Safety standards: mainly include mechanical safety, electrical safety, laser safety, non-laser safety, electromagnetic compatibility and other related standards;

-Green and low-carbon standards: mainly include energy-saving, water-saving, comprehensive utilization of resources, environmental protection, green manufacturing evaluation, green design, green services, carbon peak carbon neutrality and other related standards;

-Intelligent manufacturing standards: mainly include industrial mother machine and big data, cloud computing, artificial intelligence, Internet of things, digital twin and other new generation of information technology integration related standards.

2. Design supporting standards

Design supporting standards mainly include design, materials, parts, components, functional components, numerical control systems, tools, abrasives, measuring instruments, molds, accessories and other relevant standards.

-Design standards: mainly including industrial mother machine and supporting product design specifications and other related standards;

-Material standards: mainly including steel, cast iron, copper, aluminum, titanium and other materials performance, application and other related standards;

-Parts standards: mainly including fasteners, bearings, gears, hydraulic parts, elastic components, seals, couplings and other related standards;

-component standards: mainly including electrical components, electronic components, sensors and lasers and other related standards;

-Functional component standards: mainly include spindle components, screw, guide rail, turntable, swing head, tool magazine, tool holder, grating ruler and other related standards;

-CNC system standards: mainly including machine tool CNC system, intelligent CNC system, CNC equipment big data acquisition, high-end and popular machine tool CNC system and other related standards;

-Tool standards: mainly including general-purpose tools, precision complex tools, superhard tools, micro-blade tools, woodworking tools, intelligent tools, interfaces, tool systems and other related standards;

-Abrasives standards: mainly including ordinary abrasives, super-hard abrasives, bonded abrasives, super-hard abrasive products, coated abrasives, silicon carbide special products and other related standards;

-Gauge standard: mainly including length measurement, angle measurement, geometric tolerance and other related standards;

-mold standards: mainly including stamping die, plastic mold, die casting mold, forging die, powder molding die, extrusion die, roller die, glass mold, rubber mold and other related standards;

-Accessory standards: mainly including fixtures, chucks, dividing heads, suction cups and other related standards;

-Other standards: mainly include industrial software, hydraulic systems, electrical systems, monitoring systems, automation systems, logistics handling devices, special robots and other related standards.

3. Manufacturing Equipment Standards

manufacturing equipment standards mainly include reduced material manufacturing equipment, such as material manufacturing equipment, additive manufacturing equipment and other related standards.

-Subtractive manufacturing equipment standards: mainly including metal cutting machine tools, special processing machine tools, woodworking machine tools and other related standards;

-and other materials manufacturing equipment standards: mainly including casting equipment, forging equipment, welding equipment, heat treatment equipment, surface treatment equipment, composite molding equipment and other related standards;

-Additive manufacturing equipment standards: mainly include binder injection equipment, directional energy deposition equipment, material extrusion equipment, material injection equipment, powder bed melting equipment, stereolithography equipment, thin material lamination equipment, composite additive manufacturing equipment and other related standards.

4. Manufacturing Process Standards

manufacturing process standards mainly include cutting, casting, forging, welding, heat treatment, surface treatment, composite processing, additive manufacturing and other related standards.

-Cutting Process Standard: mainly include turning, milling, drilling, reaming, boring, grinding, grinding, honing, polishing, hobbing, interspersing, broaching, planing, sawing, electrochemical machining, superfinishing, high-speed/ultra-high-speed cutting, Cryogenic cutting, EDM, electrochemical machining, ultrasonic machining, laser machining, arc machining, plasma arc machining, electron beam machining, ion beam machining and other related standards;

-Casting process standards: mainly including sand casting, investment casting, lost foam casting, centrifugal casting, high pressure casting, low pressure casting, squeeze casting process and other related standards;

-Forging process standards: mainly including free forging, die forging, rotary forming, special forming, alloy forging, and separation, bending, drawing, forming, special stamping process and other related standards;

-Welding process standards: mainly including arc welding, gas welding, electron beam welding, laser welding, laser-arc hybrid welding, friction stir welding, resistance welding, electromagnetic pulse welding, rotating friction welding, linear friction welding process and other related standards;

-Heat treatment process standards: mainly including preparatory heat treatment, quenching and tempering heat treatment, carburizing and nitriding heat treatment, surface strengthening heat treatment process and other related standards;

-Surface treatment process standards: mainly including physical vapor deposition, chemical vapor deposition, hard chromium plating, nickel plating, copper plating, composite coating, arc spraying, plasma spraying, supersonic flame spraying, hot dip plating, hot zinc infiltration and various zinc-based coating process and other related standards;

-composite processing standards: it mainly includes turn-milling composite processing, turn-grinding composite processing, turn-milling composite processing, boring-milling composite processing, turn-roll composite processing, roll-grinding composite processing, roll-milling composite processing, roll-guided composite processing, grinding composite processing, milling-grinding composite processing, laser cladding turn-milling composite processing, high-speed composite processing, EDM ultrasonic composite processing, electrolytic EDM composite processing, electrolytic EDM composite processing, electrolytic grinding composite processing, electrolytic wire cutting relevant standards for composite processing, laser electrochemical composite processing, EDM laser composite processing, ultrasonic assisted cutting processing, etc;

-Additive manufacturing process standards: mainly include binder injection, directional energy deposition, material extrusion, material injection, powder bed melting, stereolithography, thin material lamination and composite additive manufacturing and other basic additive manufacturing processes, as well as multi-material, array, functional gradient additive manufacturing and other new process-related standards.

5. Inspection and testing standards

inspection and testing standards mainly include performance inspection and testing, reliability inspection and testing, precision inspection and testing, environmental inspection and testing and other related standards.

-Performance inspection and testing standards: mainly including mechanical properties, electromagnetic properties, hardness, composition, metallography, corrosion, surface quality, process evaluation, failure analysis, toxic and harmful substances test and other related standards;

-Reliability inspection and testing standards: mainly including fatigue life, aging test, reliability evaluation and other related standards;

-Accuracy inspection and testing standards: mainly including size, installation, coordination and other related standards;

-Environmental inspection and testing standards: mainly include explosion-proof, compatibility, noise, safety and other related standards.

6. Industry Application Standards

industry application standards mainly include comprehensive applications and typical scenarios and other related standards.

<p style="text-indent: 2em; text-align: left; line-height: 2;">-comprehensive application standards: mainly include service, communication, installation, operation and maintenance, platform, logistics and other industrial mother machine related standards;-Typical scenario standards: mainly include industrial parent machine-related standards for typical scenario application requirements in key areas such as aerospace, rail transit, automobiles, ships, construction machinery, agricultural machinery, energy equipment, and special equipment.

(I) to speed up the development of key and urgent standards

thefocuses on the key directions of high-end composite CNC machine tools, integrated die casting, precision forging, composite additive manufacturing, high-end injection molding, high-end CNC systems, high-performance functional components, etc., focuses on the needs of strong chain replenishment and industrial upgrading, accelerates the transformation of a number of major scientific research achievements into standards, intensifies the development of a number of urgently needed standards in the industrial chain, adopts a number of excellent group standards, and promotes the application of advanced technical solutions in the industry, fill the gap in the standard of key links in the upper, middle and lower reaches of the industrial chain.

(II) to promote the revision of a series of standards

thefocuses on the requirements of improving the processing stability, improving the operation reliability and improving the accuracy retention of industrial mother machines such as material reduction manufacturing, material equivalent manufacturing and material addition manufacturing, and promotes the revision of standard system in series to improve the quality level of host products. Systematized revision of a number of industrial mother machine-related basic general, design supporting, manufacturing equipment, manufacturing technology, inspection and testing, industry application standards, based on scientific and technological innovation achievements, scientific and appropriate improvement of the overall level of standards, timely elimination of a number of old and backward standards, leading the optimization and upgrading of the industry.

(III) enhanced cross fusion field standard

focusing on the integration of emerging technologies and the industrial mother machine industry, theactively carries out the development of relevant standards for the application of new-generation information technologies such as big data, cloud computing, artificial intelligence, Internet of Things, and digital twins in industrial mother machines, and accelerates the formulation of relevant data collection and digital A number of emerging technology standards such as modeling, intelligent design, digital technology, data interaction, and digital prototyping. Accelerate the development of standards for green design, green supply chain management, carbon emission reduction technology, product carbon footprint verification, energy efficiency assessment, etc., accelerate the intelligent and green development of industrial mother machines by integrating standards, and lead the high-end leap of the industrial mother machine industry chain.

(IV) to accelerate the promotion of China's standard internationalization level

theactively follows the international and foreign standardization frontier dynamics of industrial mother machines, carries out comparative analysis of the modernization level of the industrial chain of domestic and foreign industrial mother machines and the level of technical standards, and guides the advanced layout of China's industrial mother machine standardization work. We will speed up the transformation of advanced and applicable international standards into national standards, speed up the preparation of a number of foreign language versions of Chinese standards, and encourage the simultaneous formulation of Chinese and foreign language versions of standards and the systematic formulation of Chinese and foreign language versions of standards in the upper, middle and lower reaches of the industrial chain. Combining my country's standard research advantages in industrial machine equipment, technology, safety, inspection and testing, a number of international standards with international leading levels have been formulated. Deepen the implementation of benchmarking and upgrading actions, aim at advanced foreign standards, improve the level of my country's standards, and enhance my country's industrial competitiveness.

(I) to strengthen the overall planning of work

Under the leadership of the National Standards Committee and the Ministry of Industry and Information Technology, we will give full play to the leading role of the industrial parent machine standardization joint working group, strengthen the communication and liaison of relevant professional standardization technical committees, form an efficient and collaborative working mechanism, and ensure the construction of the standard system Vigorously advance.

(II) strengthen node control

Strengthen the tracking and analysis of the implementation of this plan, and do a good job of task decomposition in combination with the 2025-2026 Industrial Master Machine Standard Project Initiation Guide (see annex) to ensure that important standards are established in a timely manner and are formulated and released on schedule. Timely carry out work progress assessment, and regularly supervise and inspect the progress of key tasks in the plan.

(III) focus on domestic and international synergy

Strengthen the linkage between relevant professional standardization technical committees and domestic technical counterparts, actively connect and communicate with the International Organization for Standardization (ISO), International Electrotechnical Commission (IEC), etc., and promptly promote the development of my country's industrial parent machine superior technologies, products and services as international standards.

(IV) enhanced standard implementation

give full play to the role of competent departments at all levels, industry associations, relevant professional standardization technical committees and industrial machine standardization joint working groups, strengthen the publicity and training of standard systems and important standards, promote the active implementation of applied standards in the upper, middle and lower reaches of the industrial chain and timely feedback on the implementation of standards.